730FD HYDRAFLEX DRAPER

HydraFlex™ Draper

- Industry-exclusive HydraFlex™ Draper technology

- 30-foot operating width

- Available steel reel tine for working in tougher crops

- Available dual knife drive

Features

The 700FD Series HydraFlex Draper Platform features HydraFlex, an industry-exclusive hydraulic float system allowing for superior ground following capabilities over a wide range of crops and conditions.

Feature benefit:

- The HydraFlex system hydraulically controls the float of the cutterbar by the turn of a knob in the cab for ease of operation

- Provides exceptional cutterbar flexibility throughout the entire working pressure range for increased machine performance

- Unique cutterbar float arms offer a dual purpose, allowing for superior ground-following capabilities plus support to the cutterbar and draper belts for increased productivity

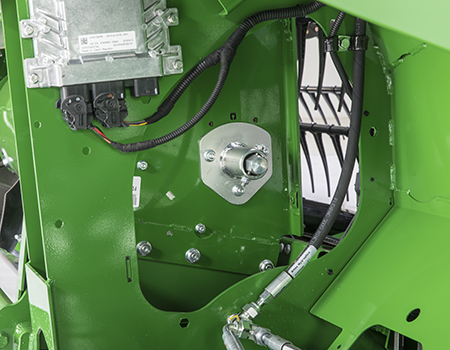

Hydraulic cylinder in the float arm

Hydraulic cylinder in the float arm Float arm on 700FD

Float arm on 700FDFunctionality

From the cab, the operator can simply adjust the armrest encoder knob which varies the hydraulic pressure in the float arm hydraulic cylinders. This controls the cutterbar ground pressure depending upon conditions.

With the HydraFlex float system, the operator varies the cutterbar ground pressure but does not affect the cutting height of the crop, even at high ground speeds. The hydraulic float system features a 19-cm (7.5-in.) float range, allowing for optimum float pressure. To lock out the HydraFlex draper into rigid mode, the operator increases the float pressure to maximum.

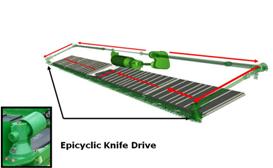

Dual knife drive

Dual knife driveDual knife drive is standard on 700FD HydraFlex™ Draper Platform for harvesting rice, tough crop, and wet or green crop conditions. This unique dual knife drive system is timed, creating the smoothest possible reciprocating knife drive system currently in the industry.

Positive, reliable, power take-off (PTO) shaft and driven, dual epicyclical in-line knife drives with built-in driveline protection provides producers with the strongest knife drive system in the industry.

NOTE: Single-knife drive is available on the 730FD, but increased cutterbar vibration may occur.

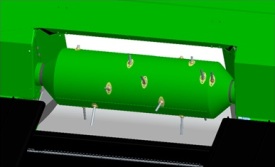

40.64-cm (16-in.) feed drum

40.64-cm (16-in.) feed drum Make adjustments to raise or lower drum

Make adjustments to raise or lower drumThe 700FD now comes standard with a dual-position drum. This allows the operator to select an upper or lower setting, equivalent to a 40.6-cm (16-in.) drum and 35.6-cm (14-in.) drum, respectively. All 700FD Draper Platforms will ship from the factory with the drum in the 40.6-cm (16-in.) position, which is the standard position. For bushy crops, such as canola, putting the drum in the upper position will allow a greater throughput.

Feed drum retractable auger finger

Feed drum retractable auger fingerA feature for 700FD Draper Platforms is a feed drum retractable auger finger to improve crop feeding at the corners of the feed drum. In some crop conditions, the crop can hesitate at the corners of the feed drum, and the retractable drum fingers keep the crop moving into the combine. This results in smoother feeding and better performance of the combine.

The speed of the side draper belts can be controlled by an adjustment on the CommandARM™ controls from within the cab. Combine software gives operators the option to slow down the side belts to a fixed speed with a push of a button on the CommandARM. Additionally, a draper belt protection system is integrated into the 700FD HydraFlex™ Draper Platform family to minimize side belt damage should slippage occur.

Feature benefit:

- Optimal performance in varying crops and conditions through side draper belt speed that ranges from 22.6 m/min to 228 m/min (74 fpm to 748 fpm) and shows on the display in the cab

- The center draper belt speed is fixed at 288 m/min (944.9 fpm) for optimal feeding to the combine feederhouse

- Speed sensors monitor the speed of the idler rollers and should major slippage be experienced, the belts will shut off and an operator warning is shown on the 4600 CommandCenter™ display

- Side belt speed reduction is designed to improve draper performance when the operator is not harvesting the full platform width or when coming out of a headland

- Increased uptime as the side belt speed reduction feature is engaged/disengaged from the CommandARM controls

CommandARM controls for S700 Series Combines

CommandARM controls for S700 Series CombinesThe 700FD HydraFlex™ Drapers offer an optional 45.7-cm (18-in.) top-crop conveying auger extending the full width of the draper to help bushy crops, especially heavy canola, feed evenly into the feederhouse.

Feature benefit:

- Maximum productivity due to smooth feeding of bushy crops such as canola that stall over the side draper belts

- Minimum time and effort required to install for bushy crops or remove for traditional crops for optimal performance in both conditions

- Available as a stand-alone option or as part of the draper feeding option with the center section seal kit for maximum performance in canola

Top-crop conveying auger

Top-crop conveying augerFunctionality:

This optional 45.7-cm (18-in.) hydraulically driven top auger has an easy speed adjustment at the right side of the platform.

It is recommended for operation in bushy or high-volume harvesting conditions such as canola.

Specifications

Compare the specifications of up to 4 models

| Key Specs | 730fd-hydraflex-draper Current Model |

|---|---|

| Cutterbar length | 9.14 m 30 ft |

| Knife drive | Base: dual knife Optional: single |

| Knife speed | 490 cycles/min |

| Pickup reel operating speeds | 6-70 rpm |

| Draper belts speed control | Hydraulic from cab (side belts only) |

| Platform | |

| Cutterbar | |

| Type | Straight-line knife drive system Cutterbar vertical flex: 154 mm 6 in. |

| Length | 9.14 m 30 ft |

| Knife drive | Base: dual knife Optional: single |

| Knife speed | 490 cycles/min |

| Cutterbar tilt | Base: hydraulic, maximum tilt 9 degree (angle) |

| Pickup reel | |

| Number of slats | Six bat poly base, steel tine option |

| Fingers | Base: nylon Optional: steel |

| Diameter | 106.7 cm 42 in. |

| Height control | Hydraulic |

| Speed control | Hydraulic |

| Reel lift | Cylinder range: 185 mm 7.3 in. Total range: 251 mm 9.9 in. |

| Reel fore and aft | Cylinder range: 359 mm 14.1 in. Total range: 616 mm 24.3 in. |

| Reel resume | Base |

| Reel reverse | Base |

| Operating speeds | 6-70 rpm |

| Operating speeds (54-in. reel) | |

| Slat reel | |

| Number of slats | |

| Diameter | |

| Height control | |

| Speed control | |

| Operating speeds | |

| Draper belts | |

| Width | Cross belt: 101.6 cm 40 in. Center belt: 177.8 cm 70 in. |

| Clean height | Cross belt cleat height: 19.05 mm 0.75 in. |

| Operating speed | Cross belt: 0 to 228 m/min 0 to 748 fpm Center belt: 211 m/min 692 fpm |

| Speed control | Hydraulic from cab (side belts only) |

| Center belt reverse | Base |

| Feed drum | |

| Diameter | 414 mm 16 in. |

| Feed drum fingers | Heavy-duty and round with breakaway notch and retainer Diameter: 16 mm 0.625 in. |

| Number of fingers | 20 |

| Auger finger platform | Dual chevron, retracting |

| Finger reach | 152 mm 6 in. |

| Drum/auger reverse | Base |

| Operating speed | 234 rpm |

| Center clean out door | Base |

| Header height sensing | |

| Type | Electrohydraulic |

| Header height sensing on the ground | Base |

| Header height sensing off the ground | Optional: three sensors |

| Auxiliary top auger | |

| Dimensions | |

| Platform length | 9.9 m 32.4 ft |

| Overall operating depth | With dividers: 2.74 m 9 ft |

| Transport width, field position | 10.27 m 33.7 ft |

| Transport width on wheel, less dividers | |

| Transport length, hitch extended | |

| Weight | |